Ductile castings are having second name- nodular or spheroid graphite iron in the market. Ductile cast iron has recently joined the family of cast irons. The metal contains spheroid graphite and provides a wide spectrum of mechanical properties that can be achieved either by making changes into specific processing variables or through various heat treatments.

Ductile castings are having second name- nodular or spheroid graphite iron in the market. Ductile cast iron has recently joined the family of cast irons. The metal contains spheroid graphite and provides a wide spectrum of mechanical properties that can be achieved either by making changes into specific processing variables or through various heat treatments.

Ductile Castings Benefits And Defects: By Leading Foundry

Ductile iron castings are made by adding magnesium/ cerium to cast iron and it was initially experimented in 1943. While maximum varieties of cast iron are brittle, ductile iron castings are a way different due to presence of nodular graphite. Solid ductile castings possess about perfect graphite spheres that make it ductile and less brittle.

Ductile iron castings are made by adding magnesium/ cerium to cast iron and it was initially experimented in 1943. While maximum varieties of cast iron are brittle, ductile iron castings are a way different due to presence of nodular graphite. Solid ductile castings possess about perfect graphite spheres that make it ductile and less brittle.

Parts Of Engine By Casting Process – Its Advantages

Engines are t he main parts of any type of machines. There are thousands of techniques which are launched for the manufacturing of engine parts for different kind of machines. We are covered with machines and all these works on the different phenomenon. Without engines, it is impossible to work for a machine. Parts of machines play a vital role in the working of such machines. There are various principles joined to the machines. Engine casting parts are now the biggest opportunity for the casting manufacturers, retailers, traders, etc. Thus they have to meet the needs and demands of the casting clients to get a stable position in the casting market.

he main parts of any type of machines. There are thousands of techniques which are launched for the manufacturing of engine parts for different kind of machines. We are covered with machines and all these works on the different phenomenon. Without engines, it is impossible to work for a machine. Parts of machines play a vital role in the working of such machines. There are various principles joined to the machines. Engine casting parts are now the biggest opportunity for the casting manufacturers, retailers, traders, etc. Thus they have to meet the needs and demands of the casting clients to get a stable position in the casting market.

Engine Casting Is Necessary Or Not?

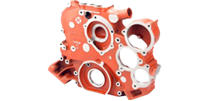

Engines are the main parts of any machine. It is impossible to work on any machine if there is incorrect engine. So we have to choose correct and efficient engine for proper working on industrial and commercial scale. Engine casting process is a process in which engines and sub parts are formed by casting process. Various metals are used for the process of engine casting. Iron, steel, bronze, aluminum, etc. metals are use to form such parts of engines. This is necessary to choose correct option of metal for such parts.

Engines are the main parts of any machine. It is impossible to work on any machine if there is incorrect engine. So we have to choose correct and efficient engine for proper working on industrial and commercial scale. Engine casting process is a process in which engines and sub parts are formed by casting process. Various metals are used for the process of engine casting. Iron, steel, bronze, aluminum, etc. metals are use to form such parts of engines. This is necessary to choose correct option of metal for such parts.

Casting Products With Different Kind Of Molds

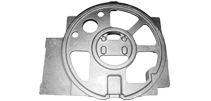

Casting is the most famous technique due to the increasing demand of the casting material. There are many cast iron foundries, cast iron manufacturers and suppliers to full fill this need of consumers in a better and proper way. Casting involves few pouring liquid metal into the mold. A mold is a hollow cavity of the required or desired shape and it is made of metal, wax and some other material. It allows pouring the metal in liquid state and cooling it till it become solid.

Casting is the most famous technique due to the increasing demand of the casting material. There are many cast iron foundries, cast iron manufacturers and suppliers to full fill this need of consumers in a better and proper way. Casting involves few pouring liquid metal into the mold. A mold is a hollow cavity of the required or desired shape and it is made of metal, wax and some other material. It allows pouring the metal in liquid state and cooling it till it become solid.

Role Of Ductile Castings In Economic Growth

The economic growth of India is based on its Industrialization. The industrial revolution in the recent times has made the economic base of India stronger. In different parts of the country various types of Industries are growing, and one of the most developing industries is the ductile industry. There are vast amount of resources present in India, and from these colossal elements the ductile are manufactured.

economic growth of India is based on its Industrialization. The industrial revolution in the recent times has made the economic base of India stronger. In different parts of the country various types of Industries are growing, and one of the most developing industries is the ductile industry. There are vast amount of resources present in India, and from these colossal elements the ductile are manufactured.

Which Metal Casting Techniques Are Used By Cast Iron Foundries?

Metal casting is a popular technique in which engineers do metalworking and pour molten metal inside a casting mold. The liquid metal is then allowed to set and then removed from the mold. The dried metal shape is later made into shape through sanding, grinding, and polishing. Cast iron foundries are using this form of metal work since many years and it is known to be one of the oldest. Most industries use this method due to its reliability and efficient output.

Metal casting is a popular technique in which engineers do metalworking and pour molten metal inside a casting mold. The liquid metal is then allowed to set and then removed from the mold. The dried metal shape is later made into shape through sanding, grinding, and polishing. Cast iron foundries are using this form of metal work since many years and it is known to be one of the oldest. Most industries use this method due to its reliability and efficient output.

Manufacturers Guide to Discover Crack in a Cylinder Head

Latest models of engine cylinder heads are manufactured with lightweight materials that are prone to crack under pressure. Cracked cylinders may give lots of troubles to an engine and loss of power is one of the examples. Cylinder head failure is generally happened by a cracked head. Cracks are formed under heat stress in the engine. Due to extreme heat stress, metal expands and cracks appear on the surface. It is critical to determine the cracks in a cylinder head and manufacturers’ guide can help you in it. You can prevent head failure by finding cracks and get them repair immediately. Continue reading

Exports of CI castings explaining corrosion behavior of cast irons

Cast iron is a material that contains high carbon/iron alloys along with silicon. Gray cast iron, malleable cast iron, ductile, and white cast iron are fewer examples. Exporters of CI castings use these CI materials to form or fabricate different components and objects. Gray cast iron contains 2 to 4% carbon and 1 to 3% silicon. These are the cheaper engineering metals. Why it is known as gray CI material? It is due to the presence of graphite flakes that make cast iron grayish or dull in color. Continue reading

Why Cylinder Head Fails? Some Tips by Manufacturers to Detect Issues in Cylinder Heads

The cylinder head is mounted on the cylinder over the top of the engine block. It helps in creating a combustion chamber by covering the top of the cylinder. Engine head gasket is then used to seal the gap between the block and head by manufacturers. There are many reasons behind cylinder head failure and one of the most common reasons is overheating. This is generally caused by loss of coolant, head gasket failure or barrier to flow of coolant. Continue reading